System Integrator Expertise

Our experience in each of the fields of testing and process technology, equipment and controls solutions, planning and project management, facility design and construction, commissioning and systems integration not only sets ASA apart, but also sets the standard for a total turnkey resource. We have a scope of internal knowledge and capabilities that enable us to undertake large, complex projects effortlessly, deliver small projects cost effectively and do both with the highest level of value.

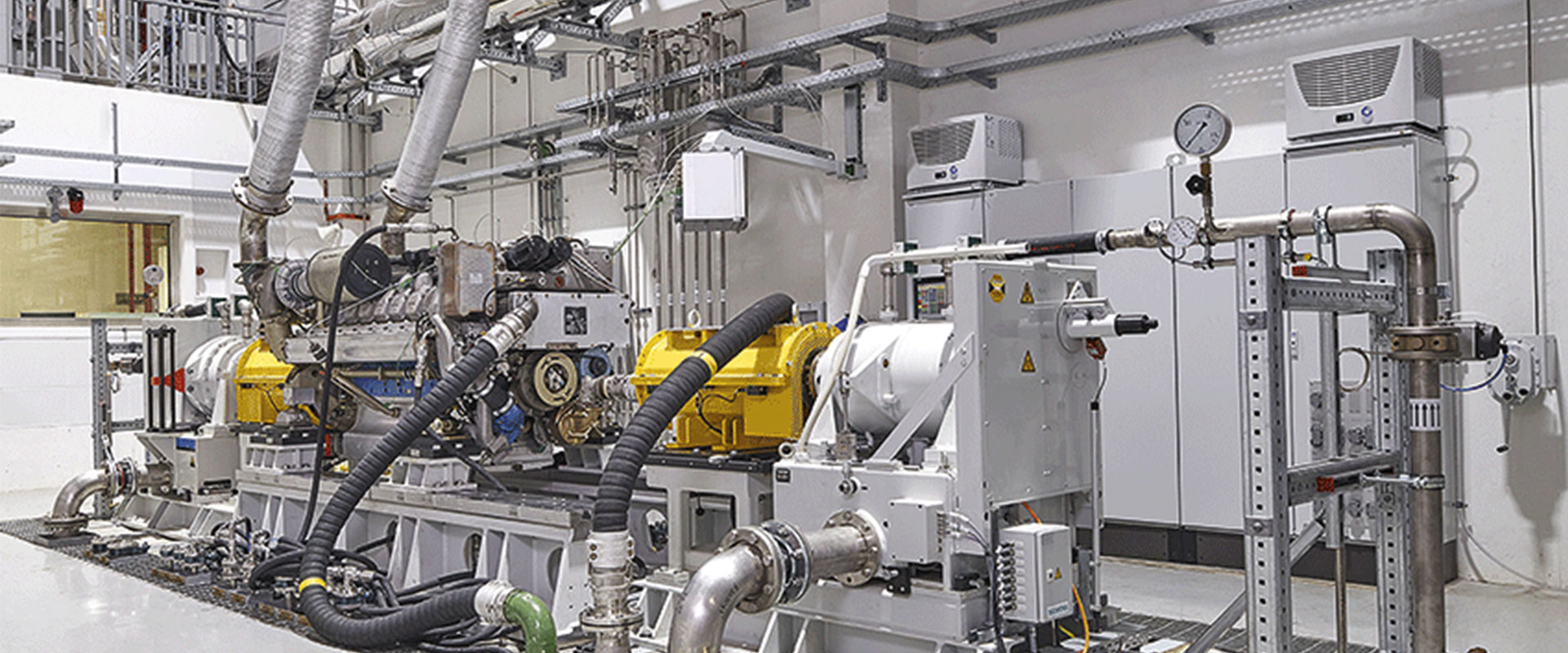

Engine and Vehicle Test Cell Solutions

ASA is at the forefront of integrated engine test cell design and delivery, providing a range of solutions for engine and vehicle testing applications, many of which include a dynamometer, mechanical equipment, fluid systems, equipment & systems controls and data acquisition. In addition to being experts in test and measurement science, the ASA team understands the details that relate to your particular application and the critical factors that will impact your test objectives.

Facility and Systems Integration Solutions

A single-source approach to integrated equipment & control systems Responsibility can make or break the delivery of a complex, high stakes, high capital investment project like an integrated R&D, industrial, manufacturing or science and technology facility. Whether your organization has facility experts, product development & test experts, both, or neither, ASA has the ability to provide a single-source of responsibility for the entire project and will get it done right – guaranteed. Our expertise in testing and process equipment, industrial and automation controls, and industry regulations, as well as deep knowledge of building design and construction, provides a total resource for your capital equipment and facility solution.

Our clients rely on ASA to manage every aspect a capital equipment project on their behalf, assuming the risk and delivering the facility that meets their requirements. From data management, systems engineering and virtual modeling to power conditioning, cooling and acoustical systems, ASA ensures your integrated equipment, facility or technical center will perform at the highest level possible.

The ASA team will work with you to understand and assess your goals and success criteria. We’ll then work with you to specify, select, procure and manage the design and delivery of R&D and process equipment. This includes designing and building custom equipment to your exact specifications and tolerances. Our in-house design and fabrication capabilities and Flexible Delivery Model enable ASA to manage equipment procurement during the design phase, which is especially helpful for equipment requiring long lead times. In addition, ASA is supplier independent, so you always get the best equipment available for your unique project.

ASA can also help you acquire, integrate and centralize data from disparate systems. This includes migration of recent and legacy data into custom or commercial systems. We also implement custom software solutions, based on proprietary hardware and software, for reporting and system integration solutions with database management systems.

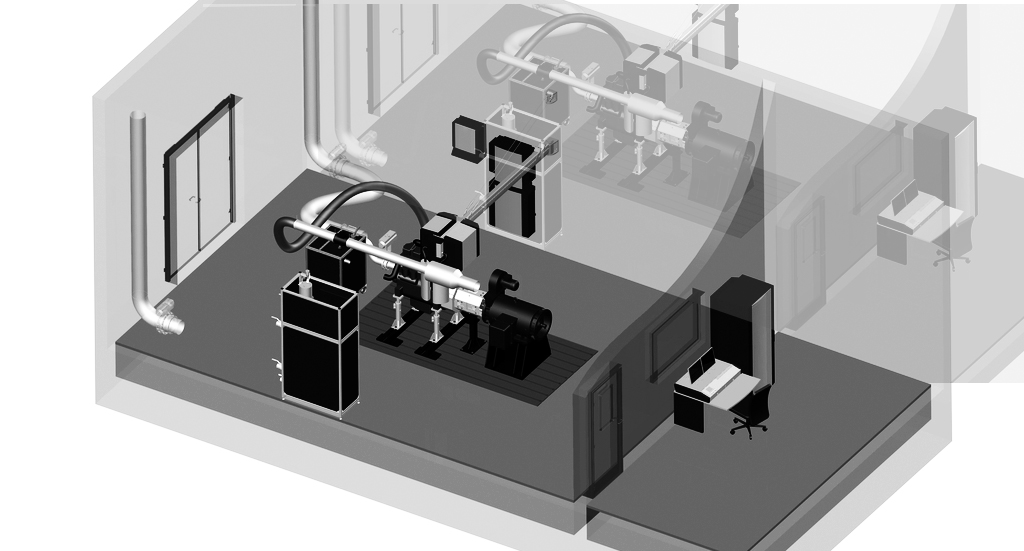

Container Test Cell SolutionsFlexible Turn Key Solution for Test Beds

ASA is a provider of Total Testing Solutions for customers requiring a turnkey solution for combustion & electrical engine, driveline and powertrain test beds. One possibility of building turn key test benches is to implement ASA test equipment into a containerized test cell. This flexible solution can be optimized to fulfil customer requirements like a structure building and has the advantage to be relocated easily.

A modular designed containerized test cell has following advantages:

- Basic module with all necessary options required by the market

- Different sizes of container modules to fit testing purpose (dimensions/application and specimens size/R&D or endurance testing)

- Easy integration on customer site

- Short final commissioning on customer site

- 100% design to customer requirements is possible

- From one test cell to complete test field, installation aligned to customer time and budget schedule

- Full cost control for customer

Standard scope of supply:

- Engine conditioning modules (Specimen/electrical power units coolant, oil, intercooler)

- Air cooling system based by outside air or chilled water

- Exhaust ventilation System

- Piping, Ducting, Cables and Works

- Fire and Gas Detections System

- Controlling System

- Installed and Commissioned

Options:

- Cooling Tower and Chiller Machines

- Combustion Air Conditioning – Temperature, Humidity, Pressure

- Fire Extinguish System – CO2 or high-Pressure Water Mist System

- Piping, Ducting, Cables and Works

- Control Room with Climatic System

- Main Electrical Supply Board

- Installed and Commissioned

Test Automation Software for Engine Testing

Automation systems have to provide innovative and flexible solutions taking the latest automotive trends into account. In addition, the best automation system is of no use if it is not stable and reliable. This concerns product quality and delivery dependability, as well as maintainability and expandability. Investment protection is constantly in focus.

Features:

- User friendly software using modern Windows concepts

- Efficient by using libraries and work flow technology

- Built using Microsoft`s state-of-the-art .NET technology, maximizing product life and your investment

- Flexible and versatile product that fits to your process

- Powerful, designed to cater for the most complex of requirements

- Extendable by a large number of additional systems and applications

- Easy to learn by using familiar user interface, a comprehensive solution for Engine testing

- Simple-to-use, graphical Workflows allow you to run the most complex of tests by simply pressing a button

- Multi-level limit alarms

- Multiple data loggers running

- Controllable user interaction and selection during a test

- Flexible display pages

- Single Test Stand or Test Field operation

- User definable project structure with multiple library support